GRAMM TEK INC. is the solution for leading manufacturers looking for an OEM supplier delivering world-class quality products at lower total cost, with the promise of excellent customer service from the beginning till completion.

For precision or functional components, from design to tooling with various kinds of material to die casting, sand casting, investment casting, centrifugal casting, forging, stamping, brazing, CNC machining, secondary machining, plastic injection molding, grinding, polishing, painting and sub-assembly, Gramm Tek Inc. proves itself in quality, service, and price as one of your most reliable sources in manufacturing of parts.

Today, GRAMM TEK INC. is IATF16949:2016, ISO 9001:2015 & PED certified and one of the few manufacturers in Asia to execute LEAN systems for supplying machined parts to the automotive, petrochemical, valves, beverage and other industrial fields of all its locations.

GRAMM TEK INC. continues to implement the top investment casting, serving renowned brand names in global markets in Northern America, Europe, and the Asia Pacific Rim. We have professional teams of engineering, quality assurance, logistic and customer service at your disposal.

- GTG was founded in 2001

- China ZS factory built in 2003

- Started China HZ factory in 2004

- DT factory started production in 2009

- US office registered in 2011

- TS 16949 qualified in 2012

- Started making braking parts in 2015

- CJ plant built in 2017 for expansion

- IATF 16949 renewed in 2018

- CJ plant opened in 2020

- IATF 16949 renewed in 2021

- CJ plant starts production in 2021

- 1st GHG emissions and carbon footprint were inspected in 2022

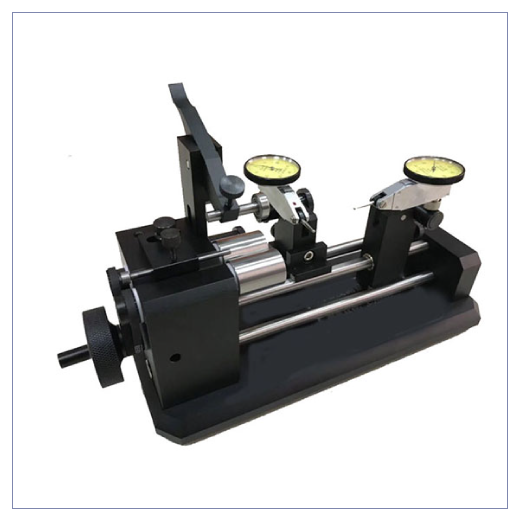

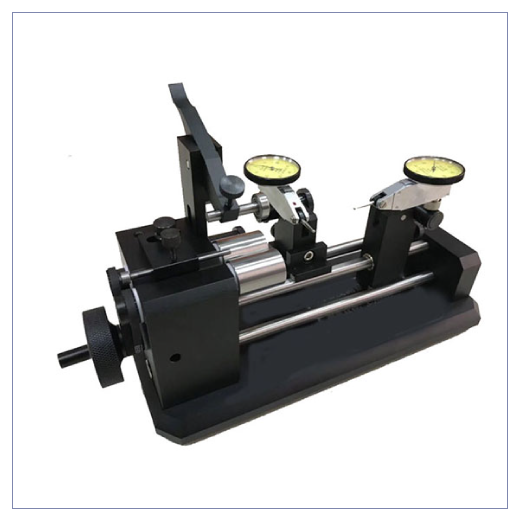

For speeding up the manufacturing development and reducing the production cost, our Engineer Department provides the service of design suggestion and proposal of cost structure for customer’s consideration orientation.

The product provided by GRAMM TEK INC. is available from blank casting, bar stock, seamless tubing, wire manufacturing, lose wax casting, sand casting, die casting, horizontal centrifugal tube casting, cold and hot forging, laser cutting, plastic injection molding and the material type from stainless steel, nickel alloy, titanium alloy, aluminum alloy, zinc alloy, copper alloy, carbon and alloy steel, cast iron, sphericity graphite iron, plastic and rubber.

In addition to provide the service of dynamic CAE analysis by 3D or 2D design files for the model of lost wax casting, sand casting, aluminum casting, zinc alloy casting, and plastic injection, we also offer simulation processes for understanding the quality and capability of cold forging, hot forging, stamping and fine blanking.

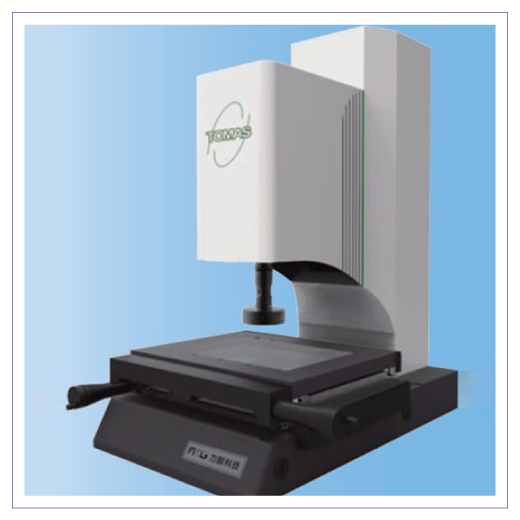

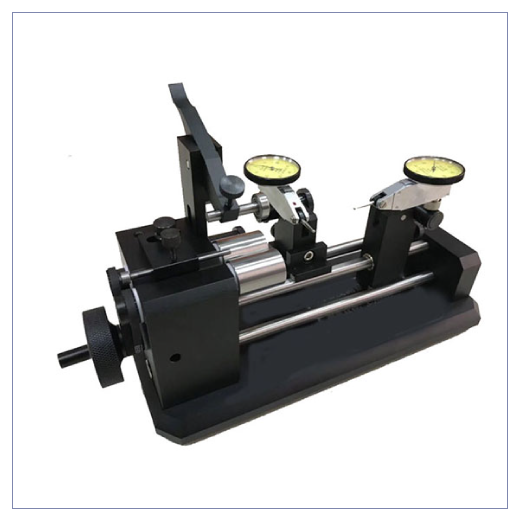

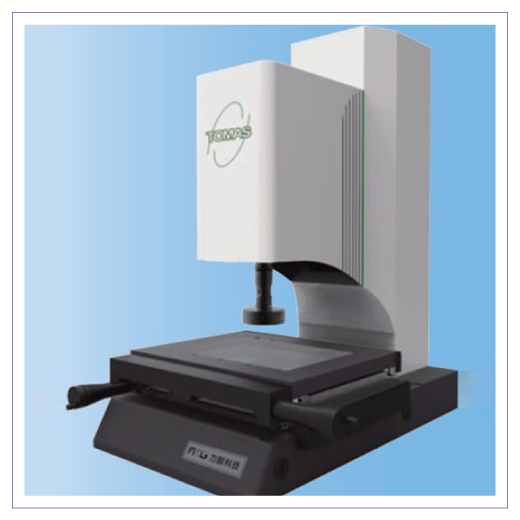

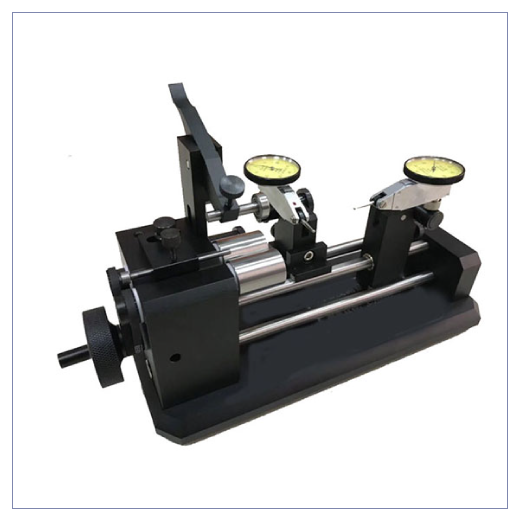

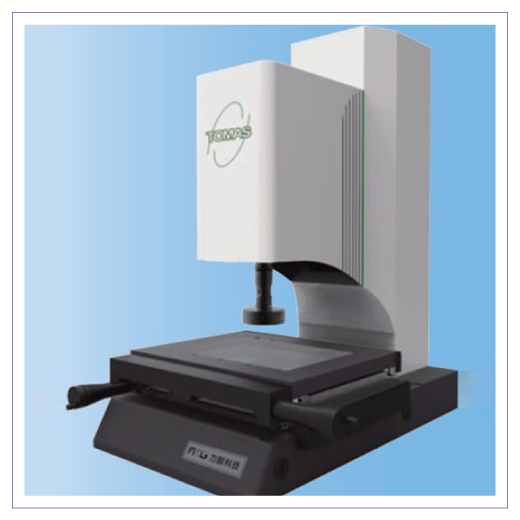

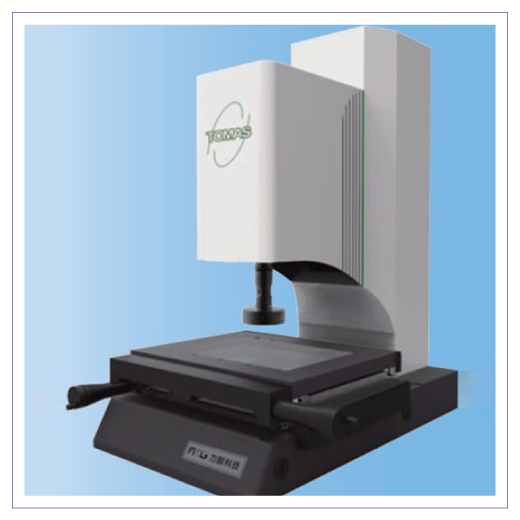

In the Quality control and assurance system, Gramm Tek Inc. is certified by IATF16949:2016, ISO 9001:2015 & PED.

We supply the best quality parts, the most efficient production and control system, the best after sales service system to our customers in the different fields, energy, beverage food and chemical all over the world.

Currently, GRAMM TEK INC., through the LEAN, TPM, 6 Sigma, DOE, AIAG’s core 5 tools production and management systems, ensures and shortens the production lead time, which also leads to cost down and provides the best possible prices conducting the Win-Win situation.